UDC SUMPS

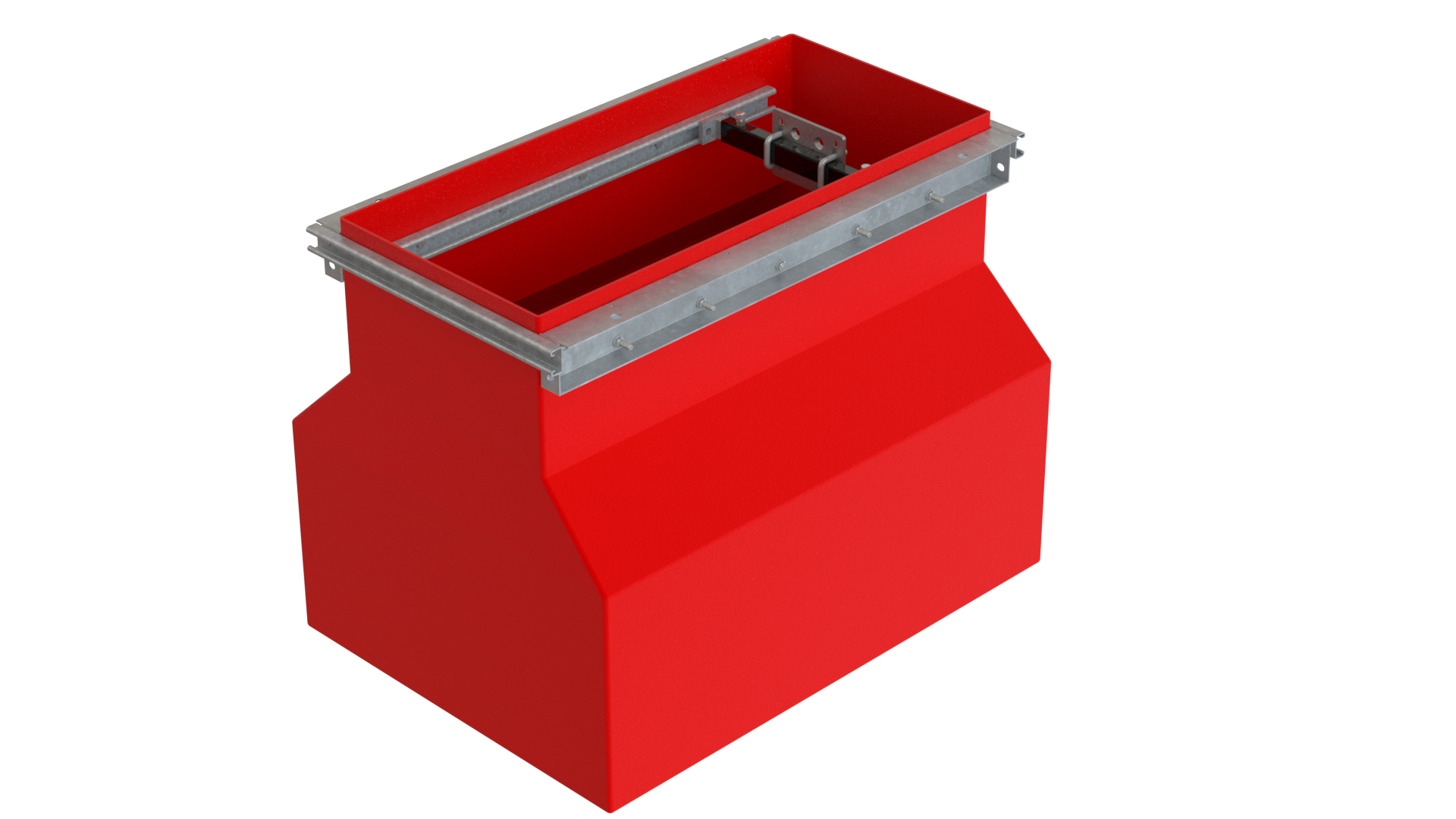

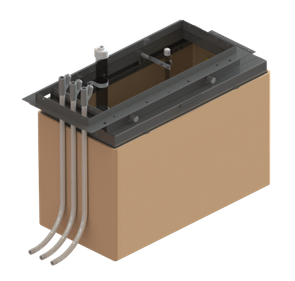

B1000 Single Wall

The Bravo B1000 Series, one of the most cost-competitive UDCs on the market today, provides needed flexibility for modern station designs with its efficient design and electrical offsets on both ends of the UDC.

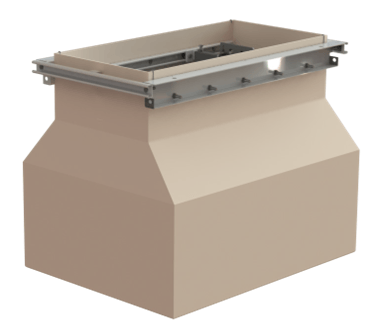

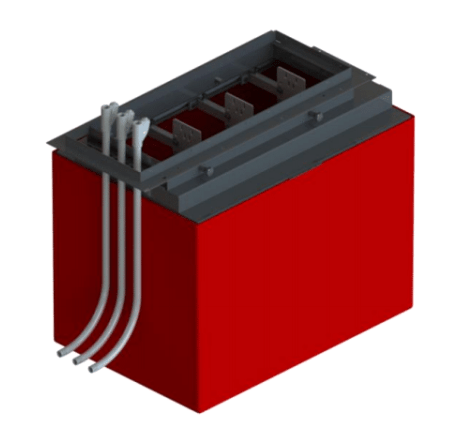

B1000 Economy

One of the most cost competitive UDCs on the market, the B1000-E Series is an exclusive offer by Bravo that features electrical offsets on both ends of the UDC, providing flexible compatibility with modern station designs.

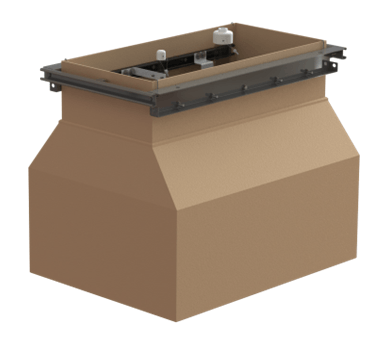

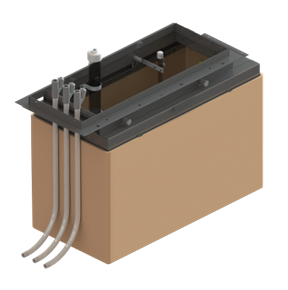

B1000 Double Wall

The B1000 Series Doublewall VPH is available in models for most modern dispensers.

B8000 Single Wall

Compatible with all common motor fuels, the B8000 Series Singlewall UDCs can be sized and tailored to any dispenser model.

B8000 Double Wall

The B8000 Series Doublewall VPH UDCs are available in models for almost all existing dispensers. This series ships under a continuous 20” Hg vacuum test.

B9000 Single Wall

Compatible with all common motor fuels, the B9000 Series Singlewall UDCs can be sized and tailored to any dispenser model.

B9000 Double Wall

The B9000 Series Doublewall VPH UDCs are available in models for almost all existing dispensers. This series ships under a continuous 20” Hg vacuum test.

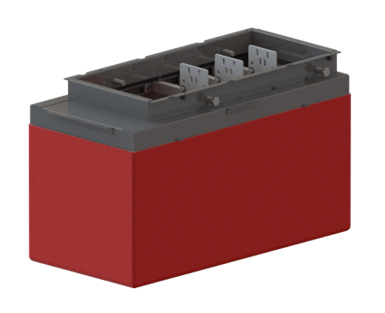

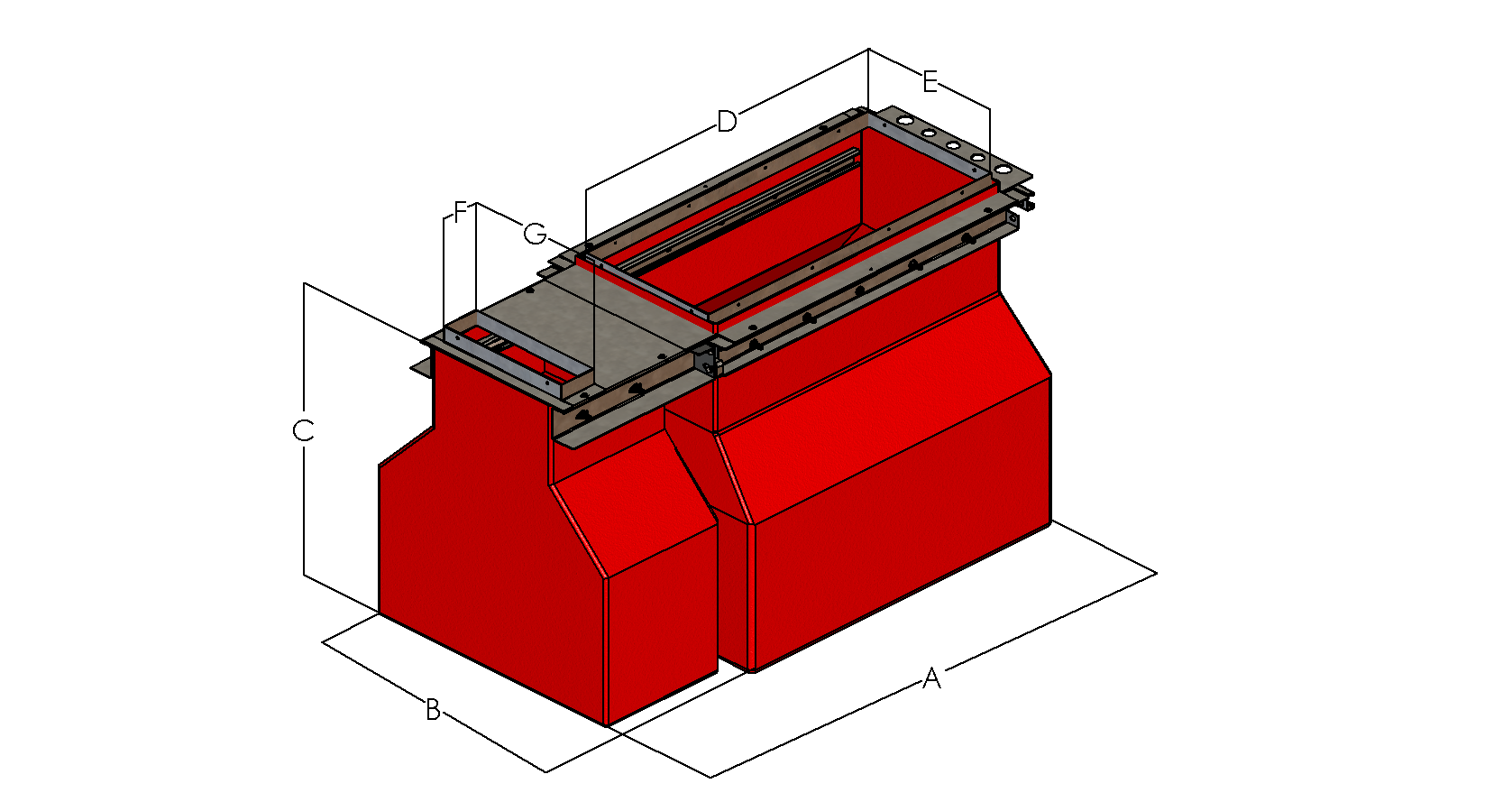

B1000 Combination Fuel/DEF

Bravo’s DEF combination UDC’s are offered in the both the B7000 and B1000 series. These UDC’s not only provide containment for the hydraulic cabinet but have a separate compartment for DEF containment.